High-precision machining (3–5 axis)

One-offs to small & mid batches — quality control & traceability since 1962

Since 1962, we have been manufacturing machined parts with consistent industrial standards. We deliver one-offs as well as small and mid batches, with a strong focus on precision and repeatability.

Machining from drawings or models in ferrous and non-ferrous materials, plastics and composites. Complex parts and tight tolerances: a production-oriented organization with a constant focus on conformity and repeatability.

Our 4- and 5-axis machining centres, combined with optimized CAM preparation, reduce non-productive time and secure quality. For higher volumes, large batches are handled in milling.

Machining capabilities

- •4- & 5-axis machining centres for high-precision work

- •One-offs, small & mid batches (turning and milling)

- •Large batches: milling only (depending on geometry and material)

- •Complex parts, tight tolerances, production repeatability

- •Quality control & traceability (materials, lots, documentation)

CAM / Programming

Optimized CAM preparation: reliable toolpaths, controlled cycle times, fewer reworks. Goal: precision and repeatability.

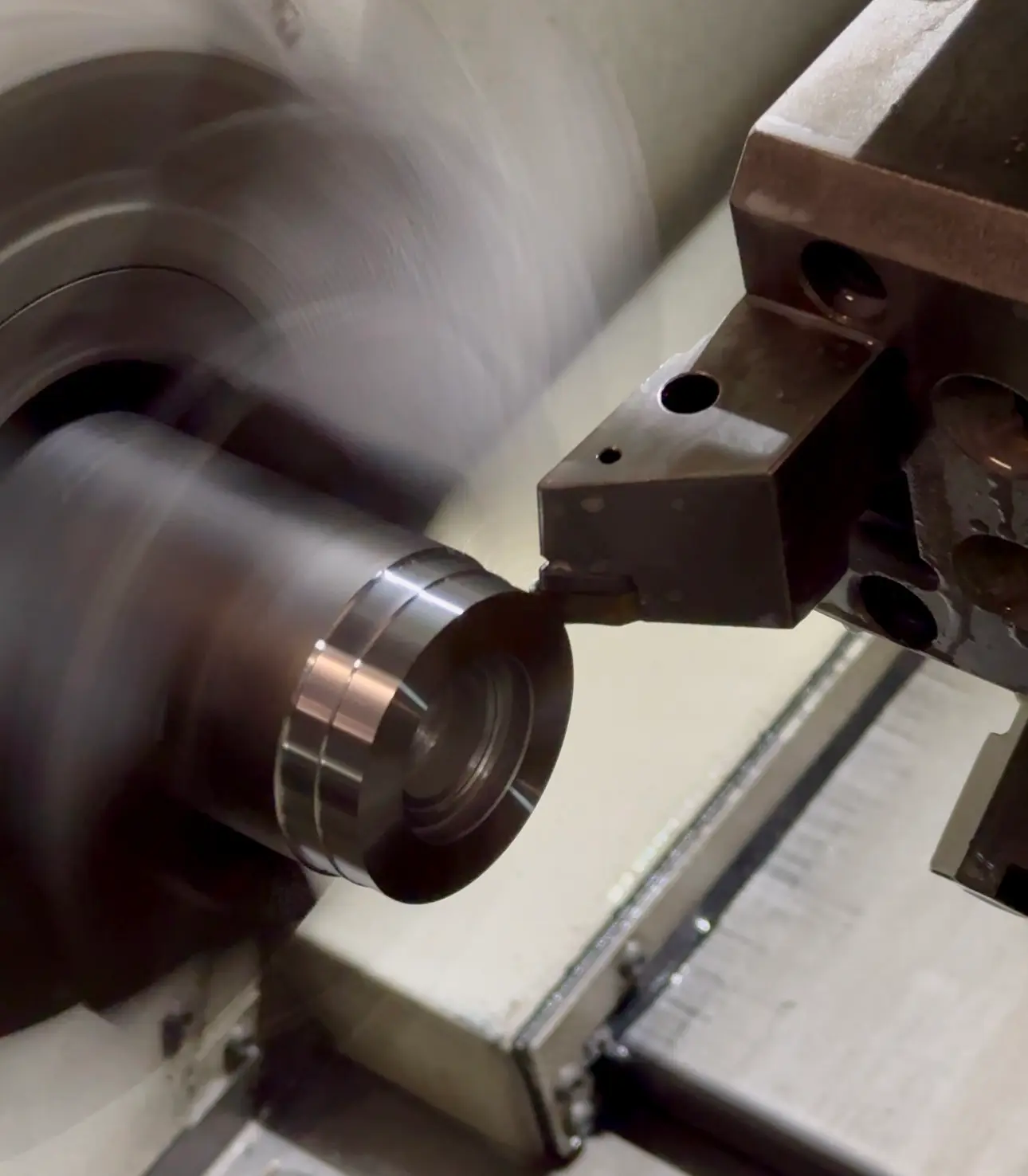

Turning

CNC and conventional turning for cylindrical parts and complex shapes. One-offs, small and mid batches.

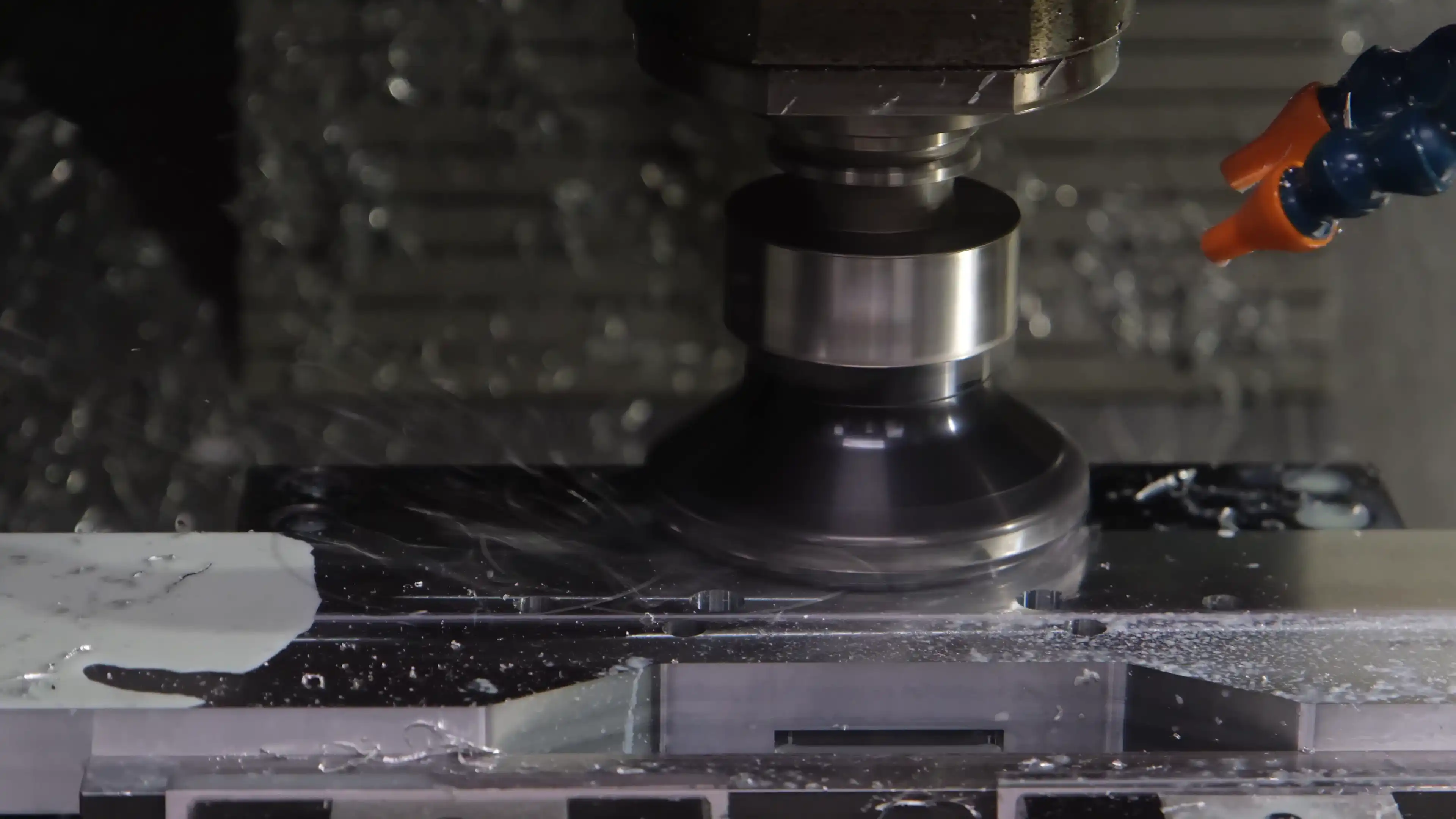

Milling

Precision milling on modern 3-, 4- and 5-axis machines. One-offs to large batches (large batches in milling only).

Grinding

Precision finishing to meet the strictest tolerances and surface requirements. Integrated quality checks.

Selected projects

Why choose our workshop?

60+ years of experience

Proven industrial know-how with an outcome-driven culture: conformity, repeatability, traceability.

Production-driven responsiveness

A flow designed to deliver fast and consistently: from one-offs to batches, without compromising quality.

Quality & traceability

Rigorous inspections, documentation management, and material/lot traceability.

Our parts are used in:

- 🚗 Automotive

- ✈️ Aerospace

- 🚆 Railway

- ⚙️ Mechanical industry

- 🔬 Medical equipment